|

|

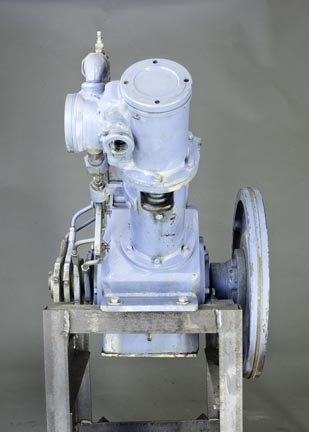

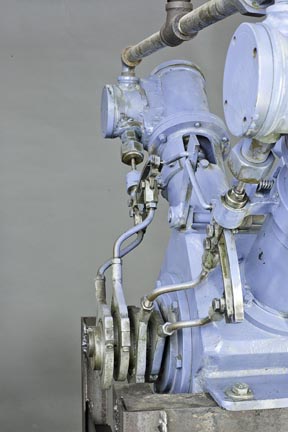

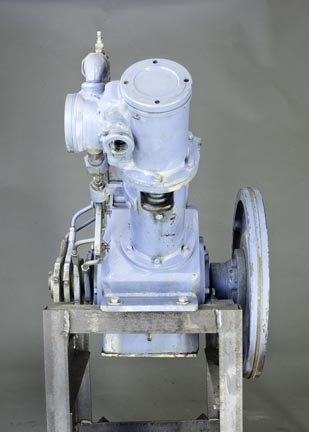

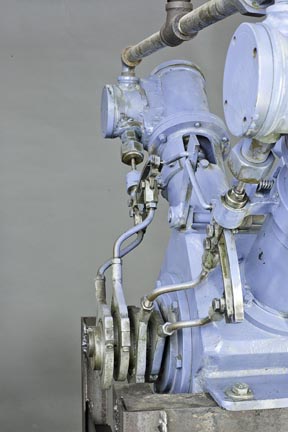

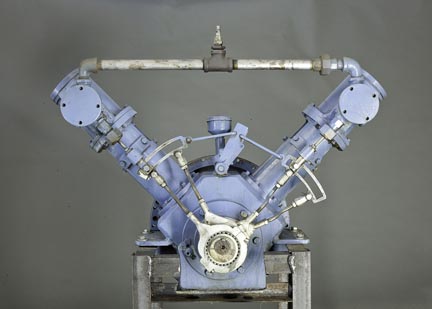

This engine is typical of almost all homemade and self-designed steam engines. It starts with a very old traditional design: the double acting simple “D” valve engine that has been around for 200 years. The steam comes into the steam chests which are the cylindrical chambers welded off to the side of the cylinders. The pistons would be very thin. This engine has well-made packing glands to seal the connecting rod. There is an opening between the cylinders and the cross heads so that steam and water will leak away and not get into the crankcase to contaminate the oil. The crosshead is quite long and cylindrical thus being heavy but also |

| |

| simple to make and machine. The crankcase is enclosed to keep the bearings clean, again something that adds weight to the engine. The valves are “D” sliding valves actuated by eccentrics to give harmonic or sine wave motion to the valve. There are a total of four eccentrics because a Stevenson reversing gear is actuated by them. This is a simple sliding block that provides both reversing and variable cutoff to the valve action. All of |

| |

|

|

| this is quite traditional. The 90 degree “V”with a single throw crank pin means that this is self-starting. At least it is self-starting at fairly long cutoff. The beauty of this engine is that someone can make it in their garage out of weldments. That means there are no castings required; merely a lot of grinding. Thermodynamically it is not efficient because of the large clearance volumes and because of the heat loss in the slide valve design and the long cutoff. It is a very easy engine to use. It is self-starting and has high torque at low speeds and is easily reversible. To operate it needs an oil injection system. |

|

|