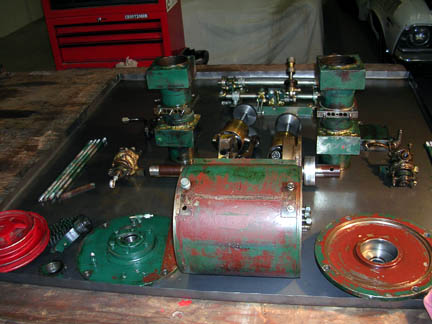

Cartland Engines:

Rotary Vane, Green, Briggs & Stratton Conversion, Launch,

and Whizzer Moped Conversion

|

|

|

|

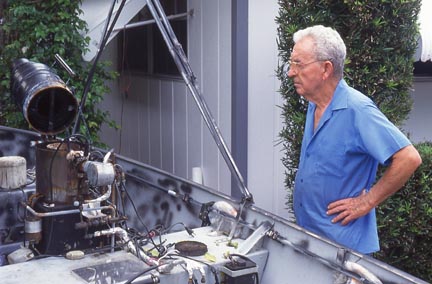

Launch |

|||

|

Bill Cartland, photos taken in 1998 and 2000 in Jupiter, Florida where Bill spent his later years working on small steam engine systems in his garage. Because of the many canals in his neighborhood Bill wanted a small boat that would drive slowly and quietly around. Bill converted everything from small model airplane engines to lawn mower engines to auto air conditioner pumps into steam engines. Most of this material is in my possession here in the shop. |

||

|

|

||

Whizzer Moped Conversion |

||

|

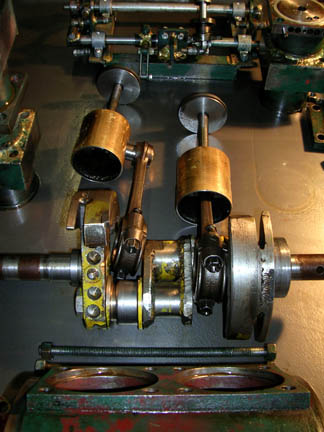

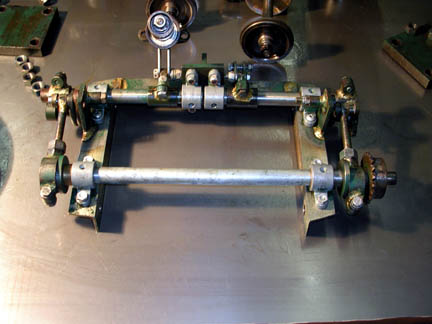

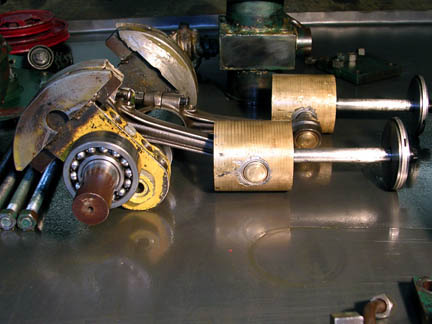

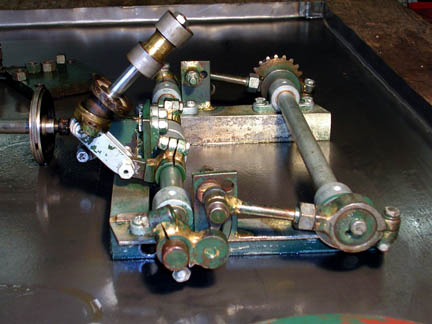

Bill Cartland Whizzer moped engine converted to steam. This is a uniflow engine, something easy to do with a two-cycle IC engine, and the intake valve is a poppet with the cam being a bump brazed onto the output crankshaft. Nice cam follower. And nice job of grinding most of the cooling fins off the Whizzer. This is in my shop.

Note the cam built into the crankshaft, the cam follower carefully hinged and the push rod to the poppet valve. The fins have been machined off the air cooled moped engine. |

|

|

Whizzer engine made by Bill Cartland and modified for poppet valve steam intake and uniflow steam exhaust. Actually the uniflow exhaust used the existing two-stroke exhaust port. The piston would need to be changed to a flat top piston instead of using the two-stroke shaped piston top. | ||