Gary Hadden Engines, Patterns,

Launch, Launch Engine and Boiler, Uniflow Engines

Contact information: jhadden1@earthlink.net

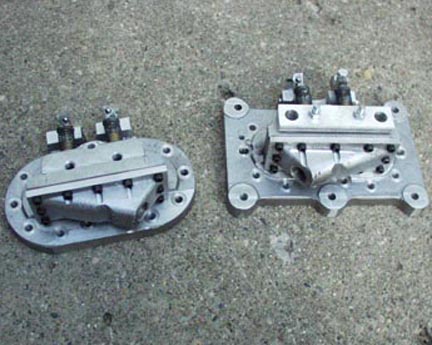

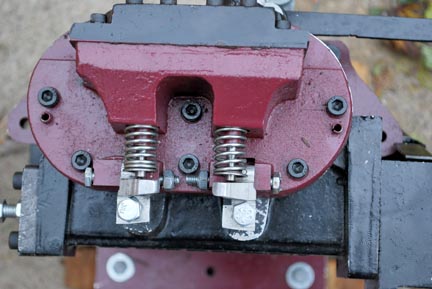

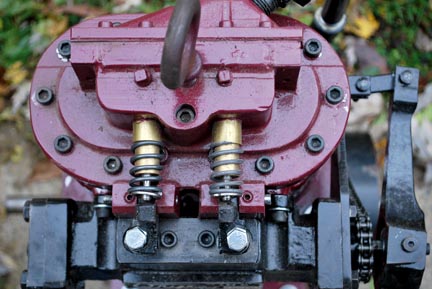

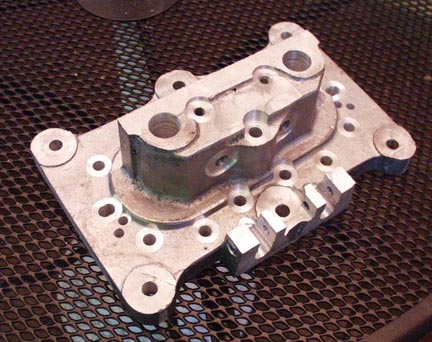

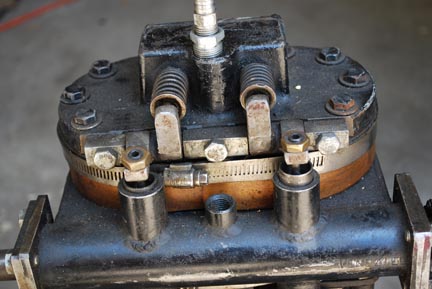

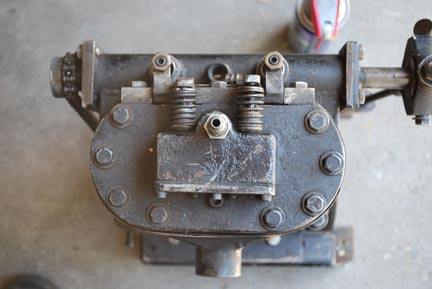

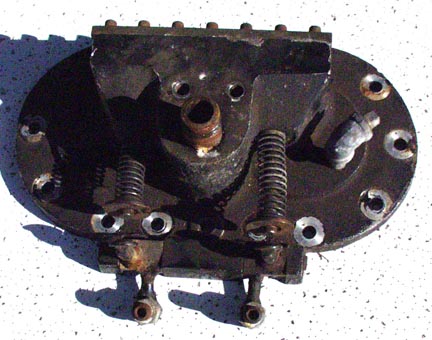

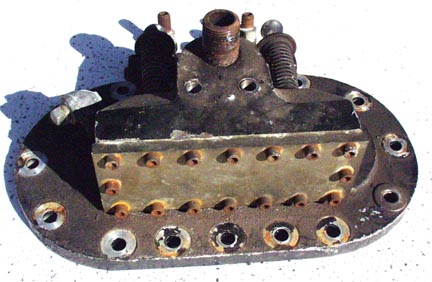

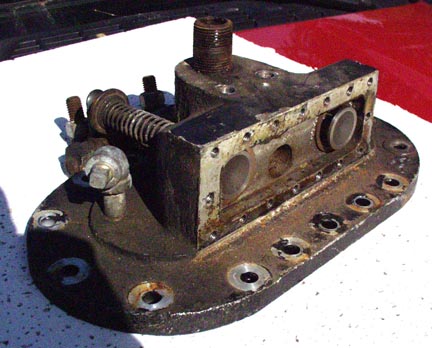

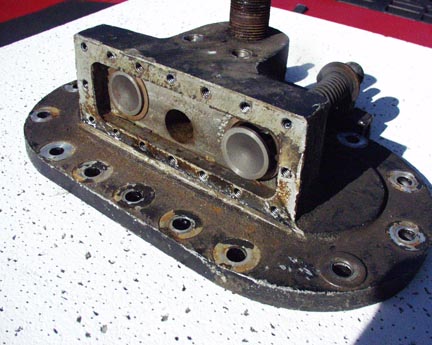

The heads use B&S poppet valves and Chevrolet hydraulic lifters. This makes for a compact engine with low clearance volume. |

||

|

|

|

|

|

|

|

|

|

|

|

(Note: Click on a picture to see a larger view and then use your browser to enlarge it further.) |

|||

|

|

||

|

|

||

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

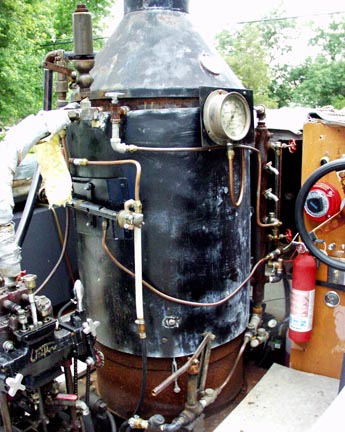

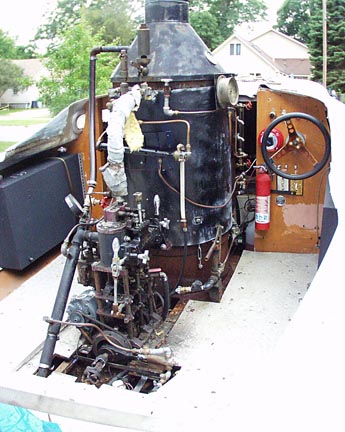

Launch, Launch Boiler and Engine |

||||

|

|

|||

|

|

|||

Gary Hadden with His Steam Powered Launch |

||||

|

|

|

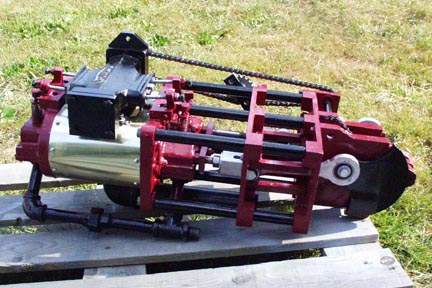

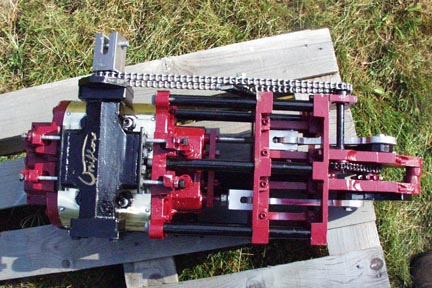

Launch Engine |

||

|

|||

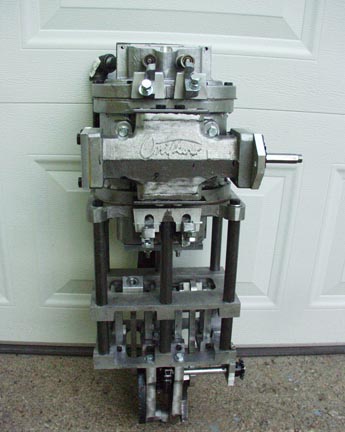

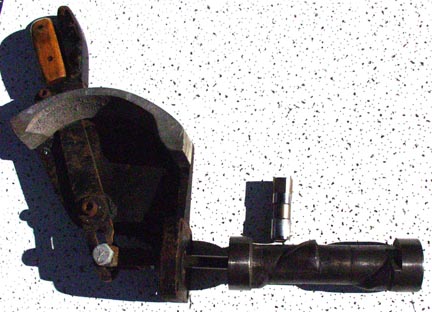

Uniflow Engines |

||

|

|

|

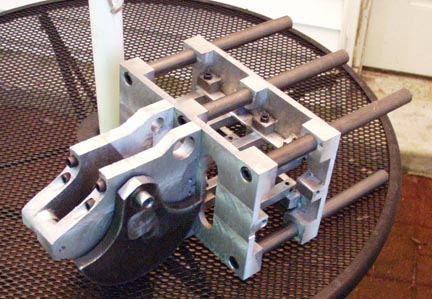

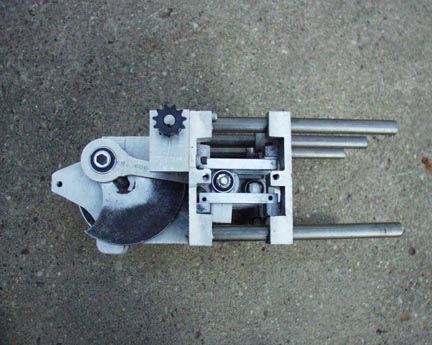

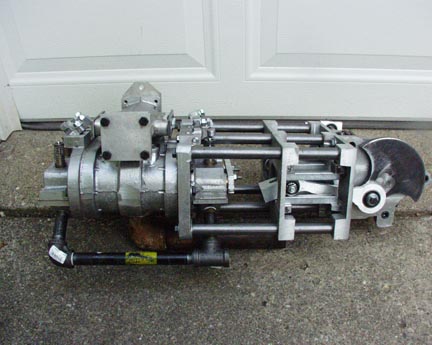

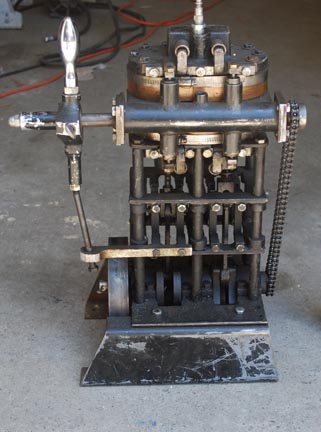

| Gary Hadden, Holly, Michigan with his self-designed uniflow steam engines; 2” and 3” bore. These are double acting uniflow with poppet valves and a very robust frame using six rods. | ||

|

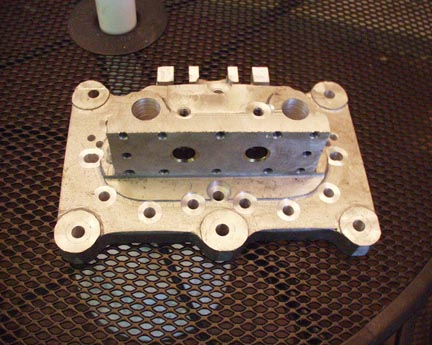

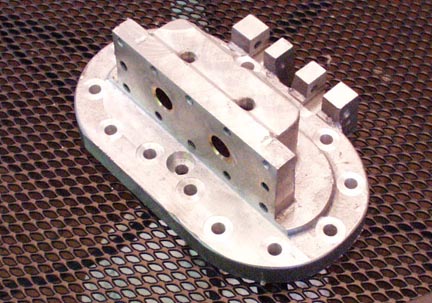

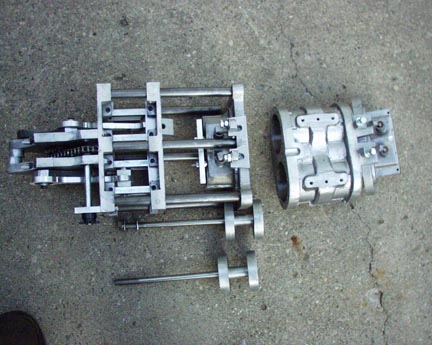

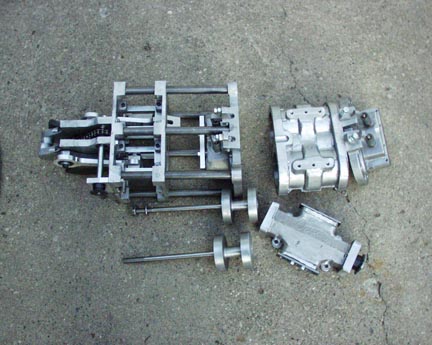

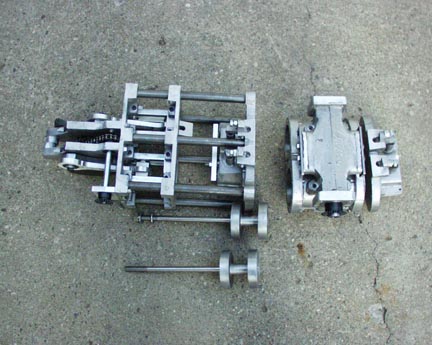

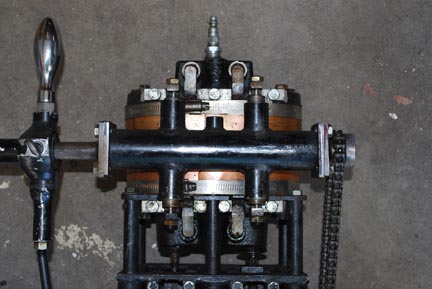

Parts of the casting kit which can be obtained in aluminum that uses a cast iron sleeve or in grey iron. Here the pistons and connecting rod are in aluminum. | |

| The engine uses the conventional Stanley style 90 degree crank for self starting. Rotating balance becomes a problem with this design at higher speeds of above 1500 rpm. |  |

|