Mobile Steam Society (MSS)

VW Conversion, Shop Boiler and Diagram

After having good chemically treated water with morphiline and other good chemicals it sat for years and the chemicals oxidized or otherwise disappeared and then the engine seized up.

We had to bang on it with a large hammer to break it free. The really clever design here is the uniflow exhaust manifold. Instead of fabricating one to go around the ports, a larger cylinder was placed over the working cylinder and the steam went into this space. It is a much easier fabrication system. Bob Edwards guaranteed the car to run and he has made a number of trips to my shop from Tennessee to work on it. The car is not a neat package and the reason is because every time some new issue came up another jack shaft was installed and a few more pumps were added.

|

|||||||||||||||||

|

|

|

|

|

|

MSS Shop Boiler |

||||

| The MSS shop boiler has a 12 volt powered water pump and a 12 volt combustion fan motor. It is designed with three kerosene nozzles, 1 gph, 2 gph, and 2 1/2 gph so that any combination of them can be selected by the car or boiler operator so that the firing rate will match the driving conditions. For years the control system was a series of temperature transducers welded to each of the pancake coils. |  |

||||

| Information from these sensors went into a computer. This was not a good design because of the large specific heat of the several hundred pounds of black iron in the heat exchanger and thus there was a large hysteresis between the temperature of the steam inside the tubes and the temperature being read by the sensors attached to the outside of the tubes. | |||||

|

|||||

| The boiler was originally designed to fit in the exact same space as a Stanley 20 hp boiler, and it ran a Stanley for years before the original Stanley boiler was reinstalled and the car sold. Eight of these boilers were made and several sold. The reason for the combustion chamber being in the middle of the coil stack was to both make the boiler short enough to fit in the Stanley and to make use of the standard ½” black iron pipe length so that a pancake coil would not need a weld in it. The boiler had 82% heat exchange efficiency. | |||||

|

|

|

Mobile Steam Society (MSS) Shop Boiler, personnel from L. to R. Ken Helmick, Tom Kimmel, Bob Edwards. MSS was founded in Oak Ridge, Tennessee by twenty or thirty nuclear engineers to make a modern clean burning thermodynamically efficient steam engine. |

||

| They started with a loaned Stanley Steam car by replacing the original fire tube boiler with a vaporizing burner with a modern monotube boiler of their own design and manufacture called the Mark II. Therefore the MSS shop boiler was of identical dimensions although horizontal in shop use and vertical in the vehicle. It was originally wired for computer control and after 30 years of disappointments due to high hysteresis because of thermal lag in the several hundred pounds of steel tubing the problem was identified and it now has analog controls. |  |

||

| The Mark II is designed to produce 500 pounds of steam per hour at 800 and 800 burning 5 gallons per hour of kerosene in a gun type burner. It is made from schedule 40 one half inch black iron tubing wound into pancake coils. It is designed so that one length of 21’ long, which is the standard length of tubing, makes one pancake coil. | |||

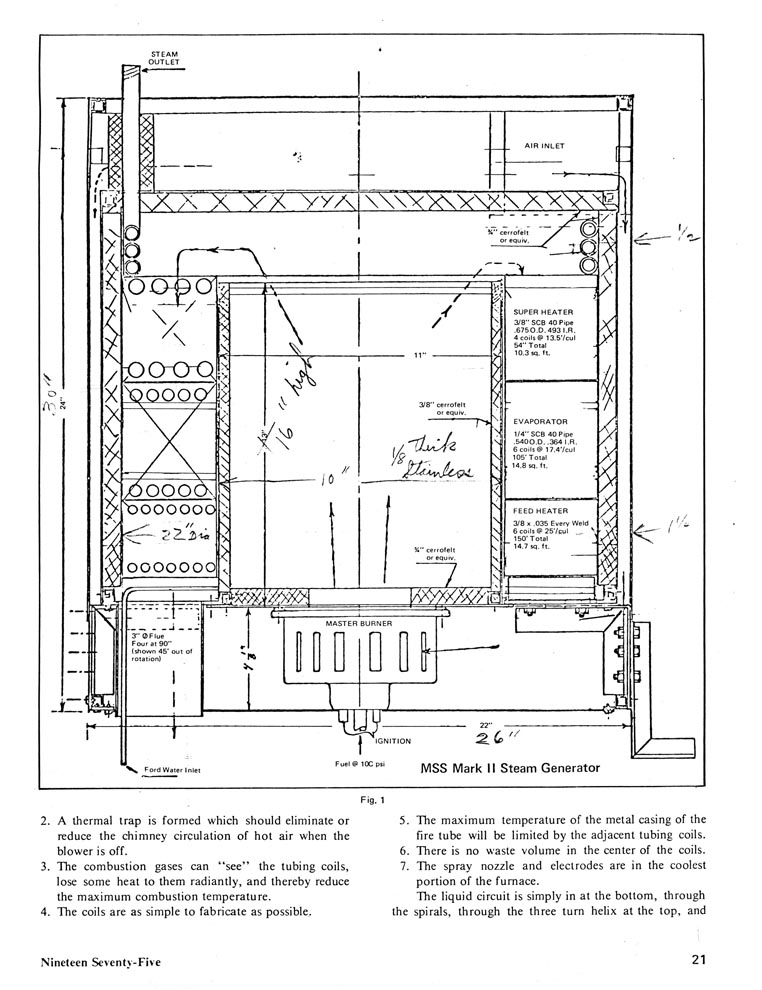

MSS Mark II Steam Generator Diagram