Rod Muller’s description of the

Little Black Engine

2x2x2 Simple 1200 RPMs 500 psi, Dated: Oct. l0, 2002

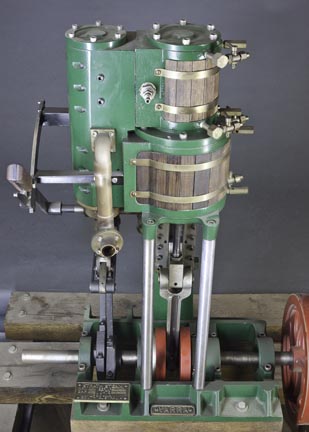

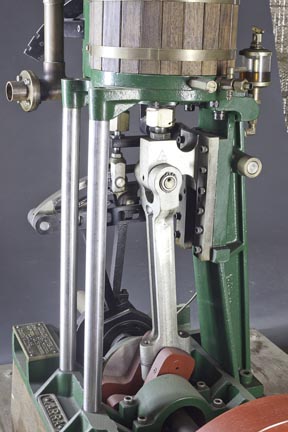

ABOUT THE VEE TWIN FREEDOM

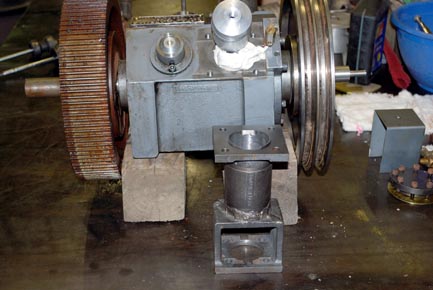

The Freedom TV95 is a double acting slide or piston valve steam engine designed for use in automotive applications.

The crankcase is either an iron or aluminum casting totally enclosed or oil filled to facilitate splash lubrication.

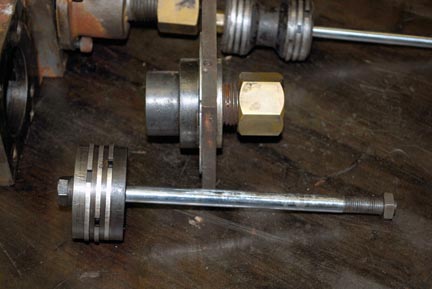

It is bored to take a single over hung SG iron crankshaft. This can be 25mm or 30mm in diameter the smaller one being good for 18 hp and the 30mm 33 hp.

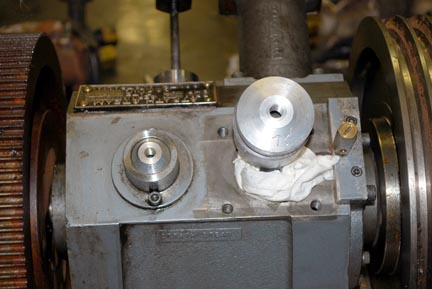

The crankshaft is supported in the centre of the crankcase with either a ball or roller race is retained in a disc carrier that is spigoted into the centre web and internally screwed to the casting.

The output end of the crankshaft runs in a single row ball race sealed on one side that is fitted into the case from the outside.

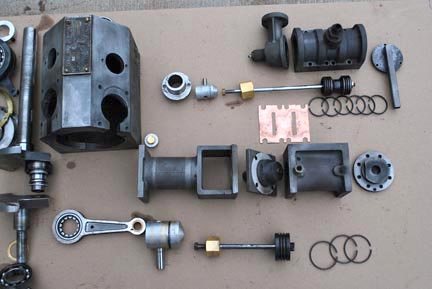

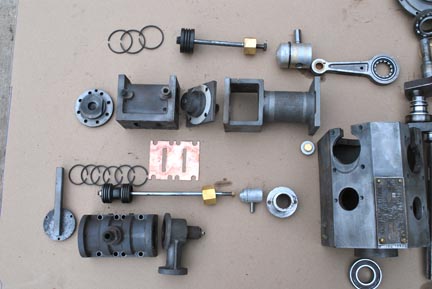

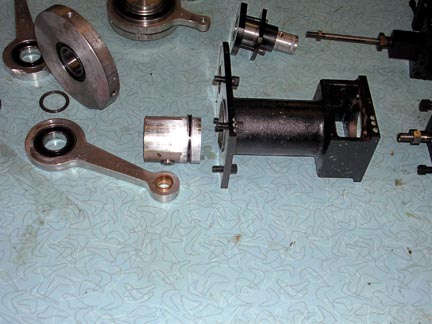

The circular trunk guides for both cylinders are made from cast iron and are bolted to the 2 faces on the top of the case which are machined at 45° to the base and at right angles to each other. They are bored and honed with a spigot on the bottom end to aid concentric location into the crankcase. They cannot be fitted until the crankshaft with rods and guides are installed.

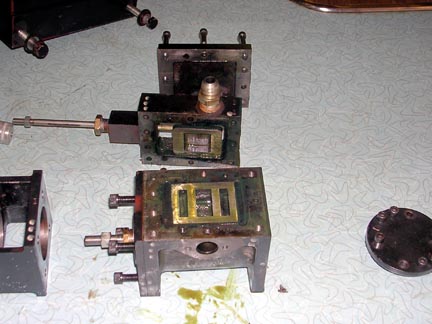

Likewise the valve drive eccentrics and rods must be loaded onto the crankshaft as it is fitted into the crankcase.

Then the valve trunk guides and trunks can be fitted.

The cylinders are bolted to the top of the trunk guides with a cover between them which incorporates the piston rod packing gland and is also spigoted into the trunk guide to concentrically align it.

The pistons are screwed into position before the cylinder covers are fitted.

Similarly the valves with spindles are screwed into there respective places before the tops are fitted.

When fitting the drive sprockets or power transmission equipment one must not tighten the retaining nut on the end of the crankshaft too tight unless the shaft has a shoulder on it as the crankshaft bearing assembly system are not designed to take high preloads or end thrust.

The sump must have oil and we recommend Mobil DTE heavy medium.

There is sump plug in the bottom of the case which could be replaced with a cock to facilitate draining off any water that may collect over time. |