John Wetz Engines:

Barrel Boiler, Table Top, Bicycle, Garden Tractor and Truck

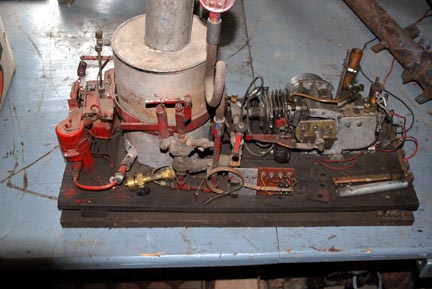

Table Top |

|||

The John Wetz table top steam power system is an excellent small demonstration of how a modern monotube boiler and bash valve uniflow engine should work. It is propane fired for convenience and has one of John’s analogue control systems. The engine is a modified weed whacker engine with aball bearing bash valve. The water pump is homemade from an aluminum block with a home made solenoid to lift the ball bearing check valve from its seat when the controls do not call for water. This unit is worth studying for its completeness. |

|

||

|

|

||

| Photo 1999 John Wetz showing Bob Bender his table top engine and closeup of the table top steam power plant. This little unit was propane fired and had everything: a copper monotube steam generator, the famous Wetz controller, | |||

| a home made water pump with home wound solenoid pulling the ball bearing off the seat for water pumping control. Below detail: The weed whacker bash valve engine was a little worn. All is on display at my shop. | |||

|

|||

|

|||

Bicycle |

||

|

This is my favorite possession. It is an example of someone with no money for materials or machine tools making a complete, well-designed, and very clever steam power system. It is a three-dimensional blueprint. | |

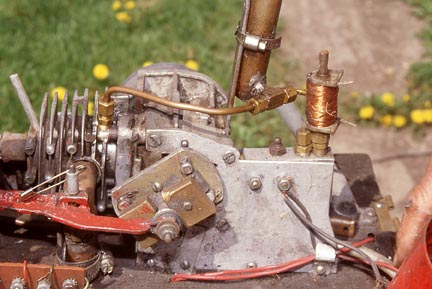

| The engine is a worn out weedwhacker engine converted to a ball bearing bash valve. The genius of this bicycle is in the burner, steam generator, and control system. The solid fuel fired combustion chamber is top loaded. Combustion air is drawn through the fuel, combustion chamber, and heat exchange coils by an electrically powered fan. When the controls call for steam pressure the fan turns on and steam is made. When steam is not made no heat goes through the coils and that is because the fuel is above the heat exchanger. |  |

|

|

The control system is John Wetz’s very clever cold water tube at right angles to the hot output steam tube and all fastened to the circular ring of spring steel. There are all kinds of feed-back loops in place. This is one of the best methods of controlling a mono-tube. It prevents flooding the boiler. Pages are needed to explain how it works. A few hours of staring at it in person is much easier. | |

|

||

The water pump is home made from a block of aluminum. The steel ball bearing check valve in the water pump can be lifted off its seat with a home made solenoid when the controls do not call for water. All in all it is a genius design. |

||

|

||

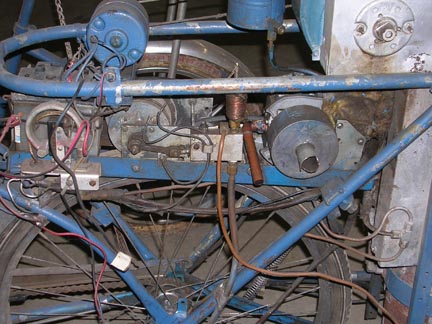

Garden Tractor |

|||

| This photo shows John Wetz firing up his garden tractor beside his barrel boiler, solid fuel fired, and the other photo is of a demonstration model of his control system for a monotube boiler. The garden tractor incorporated all of his designs. It had a very clever condenser system, oil water separator column, and burner. The engine was not that good as it was a modified Chrysler air conditioner pump that was modified to be a barrel engine with steam pistons on one end and water and oil pumps actuated at the other end. John spent yearsworking on this tractor and his goal was to always drive it in the Sandwich, Illinois steam days parade. |  |

||

I do not believe it ever made it, but this vehicle incorporates some of the most innovative steam power plant development ever done. John didnot have the luxury of having money or a good shop to work in. His genius was in the design and it is here for anyone to study. The control system is analogue. It solves all of the problems inherent in a monotube boiler control system that Doble spent his life attempting to solve. John solved it with a feed-back loop that used as inputs: the fire rate, the steam temperature, and the feed water, in such a manner that the boiler never flooded. I do not believe it ever made it, but this vehicle incorporates some of the most innovative steam power plant development ever done. John didnot have the luxury of having money or a good shop to work in. His genius was in the design and it is here for anyone to study. The control system is analogue. It solves all of the problems inherent in a monotube boiler control system that Doble spent his life attempting to solve. John solved it with a feed-back loop that used as inputs: the fire rate, the steam temperature, and the feed water, in such a manner that the boiler never flooded. |

|||

| Right below: John Wetz and his garden tractor, photo 2004. This tractor is in my shop and on display. It is the culmination of all of John’s design work and has everything starting with a wood fire, monotube boiler with good controls, and a jet condenser and radiator. There is a large water column for oil-water separation. Possibly the weakness is in the modified Chrysler air conditioning pump, a 6 cylinder swash plate design which is the steam engine. | |||

Actually, three cylinders at one end are the steam engine, bash valves and uniflow. The three cylinders at the other end are each used as pumps: water pump, oil pump, and, I think, air scavenging pump from the condenser. A swash plate is not a good design for an engine and so it never quite ran well enough. John Wetz never had enough money to do a good job of metal fabrication. A person needs to get past the workmanship and to study the basic steam power plant design. It is my opinion that John’s work is pure genius and that his designs should be copied. |

|

||

Ford Ranger Pickup Conversion |

||||

This Ford Ranger pickup converted to steam power is in my collection and proudly so. The late John Wetz lived in Waterman, Illinois where he worked as a bee keeper and thought about steam power all of his life. He was one of the most intelligent and clever steam people I have known. After working with almost no money most of his life, toward the end he decided to spend some money on his goal, a steam powered vehicle. He did not quite get it running before he died at age 93 and his three daughters gave me the vehicle to memorialize their father. |

|

|||

| Left Terry Stout, Tom Kimmel's mechanic and John Wetz. | ||||

|

Left: Chuk Williams and John Wetz, photo 2007 at Berrien Springs taken the year before he died at age 93. John’s wood fired barrel boiler installed in the back. He got this almost to run by the time of his death. His girls gave the truck to me (I had already purchased the barrel boiler from him) on condition that I store it inside and have it on display for steam club members. It is in my possession. | |||

Right: Photo 2005 John Wetz with his Ford Ranger four cylinder IC engine converted to a two cylinder bash valve uniflow engine with variably adjustable valve movement. This was John’s last steam project and one he started only after checking with his girls about spending the money. |

|

|||

|

||||

| This resulted in the uniflow exhaust being blown into the water jacket, going up into ports in the head over the two front cylinders and down through some copper coils located in the front cylinders as feed water heaters and into the crankcase. John figured that there was going to be a lot of blow-by past the rings on the power pistons and so he might as well send the rest of the steam to the crankcase because he was going to need an oil-water separator, a big one, anyhow. | ||

|

(Left: detail) |

|

|

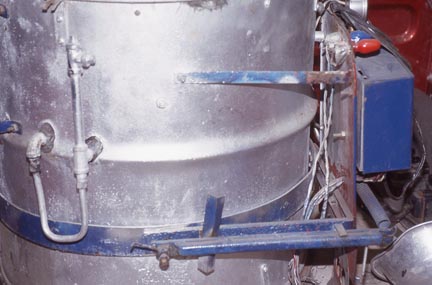

The boiler sits in the bed of the truck and is Wetz’s old barrel solid fuel boiler. The design is beyond clever. To begin with the fire is on top of the barrel above the coils. The combustion products are drawn through the coils by an old VW air cooled engine cooling fan. This fan is not well illustrated in the photos but it is run by an electric motor, belt driven to the jack shaft. The motor is wired to the steam pressure gauge so when steam is needed the fan comes on, the fire lights up, combustion takes place and steam is made. When steam is not needed the fan stops, the coals in the fire sit there with some heat going up the chimney or drying out the stack of wood, as it is a top loaded fire box and they do not burn out the | |

| Terry Stout, left, Tom Kimmel's mechanic, and John Wetz. | steam generator coils. This is very clever and only to be appreciated by a person who has tried to operate a steam vehicle with the fire underneath the steam generating coils such that the fire cannot be turned off at will. | |

|

|

| The boiler controls are the most clever ever. There is an intake water pipe located in the fire and cross-wise with the outgoing superheated steam pipe located right above the water intake pipe. When the fire gets hot both pipes expand. When the superheated steam gets hot the steam pipe expands. When cool incoming water is pumped into the steam generator; that pipe contracts. If a person thinks about this for a year or two and continuously refers to the original to study the layout, they will begin to figure out how the feed-back loop works. What happens is that the monotube boiler does not get flooded as happens to every other monotube boiler in the entire world. Doble spent his life fighting this same battle and his idea of the normalizer as a feedback loop is not near as clever as John Wetz’s idea. |  |

||

John Wetz did not have any money when working on the barrel boiler as can be seen with the Bourdon tube, made by pounding on a piece of tubing with a rock. Everything else was salvaged. For the truck John wanted to have the perfect water pump and so he had Bill Ryan machine one that pumped water, pumped lubricating oil, and pumped something else. I think that something else was the air pump to keep a vacuum in the condenser. Everything is here for a functioning steam power plant. |

|||