Williams Bus Engine and Boiler

|

|||

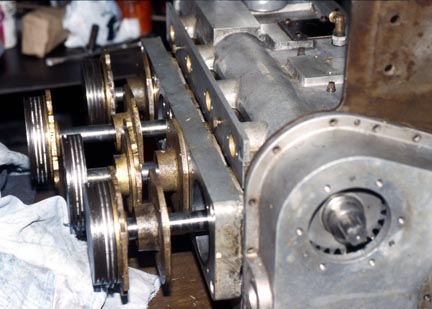

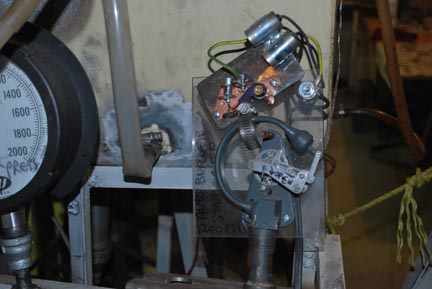

| A.C. powered oil pump. After scoring the crankshaft and two connecting rod big ends this oil pressure pump was added. It was turned on before the engine was turned over thus providing 100 p.s.i. oil pressure to the crankshaft bearings. | |||

Boiler Photos: |

||

(Click on a picture for a larger view, then enlarge it further with your browser.) |

||

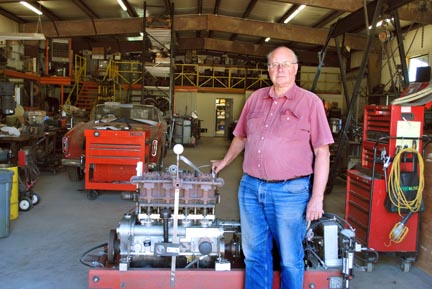

Peter Nuskey and the Green Monster boiler showing the end with the blower fan. This is a Babcock & Wilcox type of a boiler made by the famous Harry Peterson for Howard Landon’s Green Monster car, the one with a Doble “F” engine in it. It is being used as a shop boiler here to run dyno tests on the Williams bus engine. |

||

|

|

||

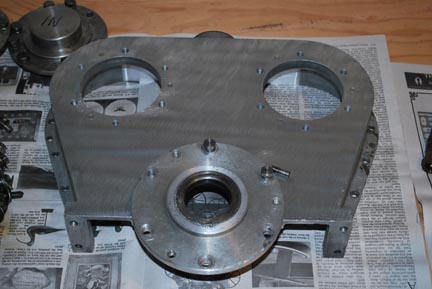

| Fuel pump end of the Green Monster boiler. | Water level control end of boiler. | ||

|

|

||

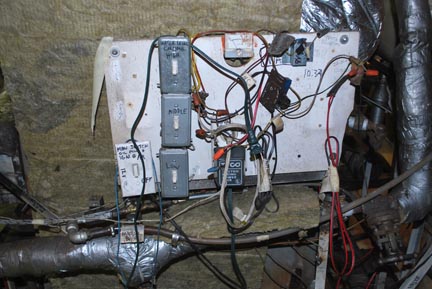

| The Green Monster Car | Bourdon tube pressure control switch for the boiler | ||

|